The application of nanotechnology in polymer materials processing is one of the research directions of KMD Plasticizing Technology. The Eisvogel color series of nanofunctional materials is a product range utilizing KMD’s nanotechnology to disperse pigments in a polymer matrix in the form of independent nano pigment particles to obtain polymer-based nano materials. When used for coloring polymers, this nano material can not only impart strong colors to the polymer but will also exert numerous beneficial effects due to its nano properties, especially in coloring microfibers.

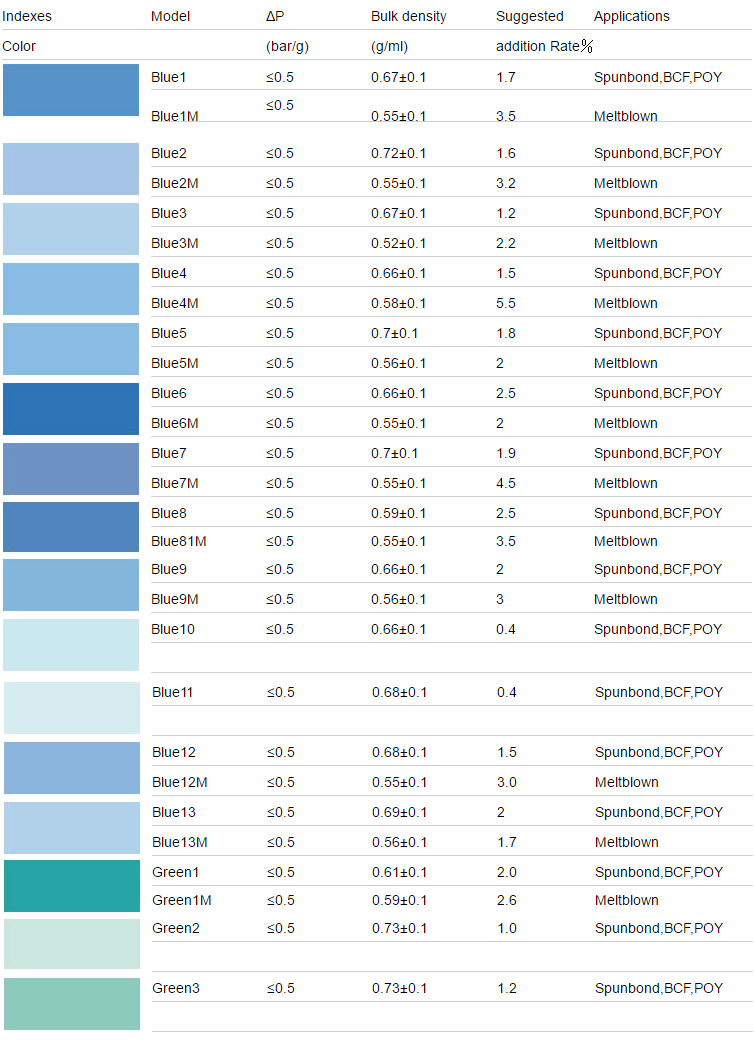

Benefits in coloration of meltblown microfibers and application advantages see information above.

Remarks:

1. The carrier of these products is a PP grade for meltbiown applications,for addition prior to spining.

2. White translucent particles,Φ3×3mm.

3. Appropriate adjustments in spinning parameters may be needed depending on circumstances.

4. Material must be stored in a dry state for use.

5. Package:25kg/bag or 500kg/case.

6. Changes in specifications reserved,please note our latest information releases in each case.

The Core of Eisvogel nanotechnology

Nano grade particles are round in nature. How to make each particle remain and exist independently and still maintain the nano state when using the nano particles applied to final application environment is a big technology challenge in the industry today.

The core of Eisvogel nanotechnology is that it ensures each pigment particle is coated and isolated in its original appearance and size, and prohibiting the agglomeration in the process of product realization. The original shape and size of nano particles is well protected in the chosen polymer.

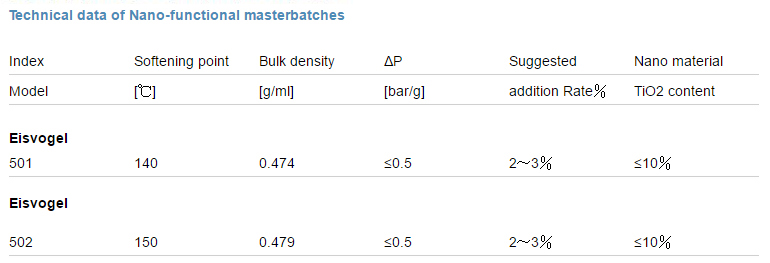

The application of nano-technology in polymer materials processing is one of the research directions of KMD Plasticizing Technology. Nano-functional materials are based on organic and inorganic nanoscale materials and a polymer carrier material (matrix).Using KMD’s nano-technology,these basic organic or inorganic nanoscale materials are separated into individual nanoscale particles with spherical,strip or other irregular shape and homogenously dispersed in the matrix. The resulting polymer based nano-functional material is supplied as granules of Φ3×3mm for application convenience. The nanoscale effect will provide a variety of advantageous features,especially in microfiber applications. This technology can also be applied to the pigment dispersion in microfibers.

Enhances the buffer ability of melt materials,effectively buffering the impact of temperature and material index fluctuations.

Markedly prolongs the spinneret cleaning cycle by about 50% compared to conventional coloring materials.

Significantly reduces melt drops and fiber breakages,potentially improving the stability of fiber production.

Achieves approx.20% increase in fiber strength.

Improves the hydrostatic pressure resistance of SMS nonwoven fabrics by approx.6~25%.

Improves material elongation behavior,enabling to spin finer fibers.

Improved comprehensive performance index of superfine fibers.

Reduction in nonwoven defect rates.

Ability to decrease nonwoven gram weights while maintaining fabric properties unchanged.

Energy savings and reduction in emissions.

Lower cost of production for nonwovens.

Significantly improved comprehensive performance of nonwoven fabrics,e.g.,hydrostatic pressure resistance value,softness,filterability,air permeability,fabric appearance,etc.

Enhanced characteristics of the nonwoven product after finishing treatment due to the surface energy of nano materials.

Remarks:

1. Material form:granules,Φ3×3mm.

2. Appropriate adjustments in spining parameters may be needed depending on drcumstances.

3. Material must be stored in a dry state for use.

4. Package:25kg/bag or 500kg/case.

5. Changes in specifications reserved,please note our latest information releases in each case.