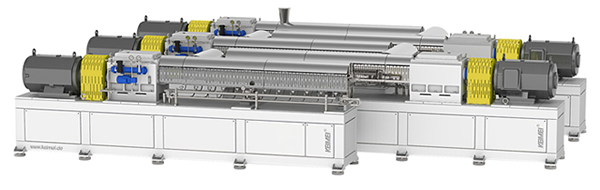

Multiple-Stage Blending Reactor :

A multi-stage blend reactor is formed by a number 'n' of mixing extruders (twin- or triple-screw type) plus the associated control devices. As shown in the illustration, the structure of each twin- or triple-screw extruder is the same as for the conventional unit, e.g., the cylinders, screw elements, shaft, gear unit, etc., are standardized. Likewise, the same design sizes and models are used (ø12, ø24, ø38, ø53, ø67 and ø 97). As for the power source, heating method and insulation characteristics, each system must be individually configured to address the materials and reaction characteristics of the specific application.

Suitable fields of application:

Suitable for polymer synthetics reaction and physical processing of some special polymers, for example, the preparation of polymer-based nano-composite material, dissolving of polymer in ionic solvents or critical gas, pyrolytic polymer reactions, etc.

Main characteristics:

Compared to a conventional tank reactor:

1. Flow dynamic response;

2. Homogeneous reaction without excessively vigorous reaction or lag effects between zones, resulting in:

Adequate mixing: thorough dispersion or mixing without stagnation points even when homogeneous mixing at the micro or nano level.

As a result, more and smaller particles may be present in the reaction system and will react simultaneously due to more even intermixing at any given time – a key advantage in high-viscosity polymer reactions which is not achievable with a tank reactor;

3. Uniform molecular distribution throughout the product;

4. Self-cleaning function, which prevents material deposits during the mixing process;

5. Homogeneous large-area heat input and dynamic heat transfer behaviour enables uniform heating of the material;

6. Reliable dynamic temperature control prevents disturbances in the material flow and the resulting incorrect measurements;

7. High control accuracy, can achieve control of fixed point sampling;

8. At fixed points to add different materials is according to the reaction state and phase, instead of mere "blind" time-based addition of materials into the reactor vessel, as conventional tank-type reactors;

9. Low energy consumption;

10. No excessively vigorous reaction;

11. High level of safety and no risk of explosion due to the reaction of the flow process;

12. Accurate process control based on actual reaction status rather than just time-based management;

13. Fast, accurate and controllable heat exchange;

14. Facilitates removal of volatiles;

15. Easier removal of reaction residue;

16.Superior convenience for production management;

17. High productivity;

18. High yield;

19. Low operating costs, due to:

• High equipment versatility, standardized parts and accessories;

• Direct heat transfer with high efficiency;

• Time and energy savings due to synchronous, uniform and very efficient blend reactions with more particles in an extended size range;

• Reduced material consumption due to high yield;

• Convenient process management and realization of volume production runs;

• No hidden cost associated with safety risks;

• High process stability providing controllable benefits.

Multiple-Stage Blend Reactor

Two-Stage Blend Reactor(Two-Stage Twin Screw Extruder)

A two-stage blend reactor is composed of two twin-screw or triple-screw extruders.

Two-Stage Twin Screw Extruder

Main Characteristics:

1. Transformation of material from a highly elastic to a viscous flow state, i.e., suitable for blending of special polymers;

2. No limitation to extend the L/D ratio without reduction in input torque (essential for blending some special polymers);

3. No limitation to extend the L/D ratio without any loss in screw/barrel precision, yield or mixing effectiveness;

Suitable fields of application:

Suitable for physical processing of some special polymer and basic chemical conversions, e.g., production of polymer-based nano-composites, blending of multiple polymers, blending of polymer and inorganic powder, etc.