Contact Us

Contact Us

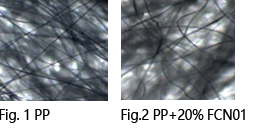

The application of nanotechnology in polymer materials processing is one of the research directions of KMD Plasticizing Technology. The Eisvogel color series of nanofunctional materials is a product range utilizing KMD’s nanotechnology to disperse pigments in a polymer matrix in the form of independent nano pigment particles to obtain polymer-based nano materials. When used for coloring polymers, this nano material can not only impart strong colors to the polymer but will also exert numerous beneficial effects due to its nano properties, especially in coloring microfibers.

Benefits in coloration of meltblown microfibers and application advantages see information above.

Remarks:

1. The carrier of these products is a PP grade for meltbiown applications,for addition prior to spining.

2. White translucent particles,Φ3×3mm.

3. Appropriate adjustments in spinning parameters may be needed depending on circumstances.

4. Material must be stored in a dry state for use.

5. Package:25kg/bag or 500kg/case.

6. Changes in specifications reserved,please note our latest information releases in each case.

Electret Masterbatch FWM03 is made by nano electret technology, which is specially used for the production of meltblown nonwoven. It could significantly improve the filtration efficiency of PP meltblown nonwoven with a low addition proportion.

Features:

1. Apply electrets, to improve the ability of charge capture and storage. With the increase of the charge density on the fiber surface and the fiber web, the charge holding period become longer, and the filtration efficiency of the meltblown nonwoven fabric is significantly improved.

2. Reduce the defects such as melt shot and broken fibers during the process of meltblowing process. Enhance the melt strength, easy to draw the fiber. Improving the spinability without blocking screens and spinneret, and enhance the fiber strength and mechanical properties.

3. Could make the fabric with high-loft effect, realize three-dimensional web formation and eventually increase the fabric thickness. Meantime, the air resistance is relatively reduced and the fabric uniformity is improved.

Applications:

PP meltblown nonwoven

| Technical Data of Fiber Crimping Nanomaterial | ||||

|---|---|---|---|---|

| Model | Suggested addition rate | MI(g/10min) | FPV(bar/g) | Appearance(mm) |

| FCN01 | PP : FCN01= 4:1 | 1050±200 | < 0.5 | 3*3 |

| Experiment data (only for reference) | ||||

|---|---|---|---|---|

| Material (Meltblown Non-wovens) | Grammage(g/m2) | Differential pressure (Pa) | Filter performance (Flow rate: 87 L/min) (Test agent: NaCl) | Dust holding capacity |

| PP | 35 | 115 | ≥ 99.7% | - |

| PP+FCN01(4:1) | 35 | 89 | ≥ 99.1% | - |

| Technical Data of Memory Nanomaterials | ||||

|---|---|---|---|---|

| Model | Suggested addition rate | MI (g/10min) | FPV (bar/g) | Appearance (mm) |

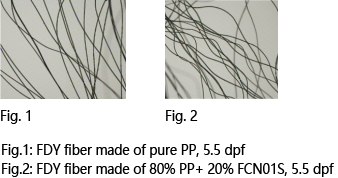

| FCN01S | PP : FCN01S = 4:1 | 40 ± 10 | < 0.5 | 3*3 |