Machines with exceptional capabilities – thanks to our special design

1. A three-start screw as core equipment.

2. Coaxial transmission: Ambient and equipment temperature changes, installation irregularities, vibrations and other

external factors will not impair the operation of the coaxial power transmission unit – a benefit of our machine's unique chassis

technology.

3. Meshing clearance: a uniform screw engagement clearance reflecting high-precision component machining is the basic

guarantor of superior plasticizing performance in your application.

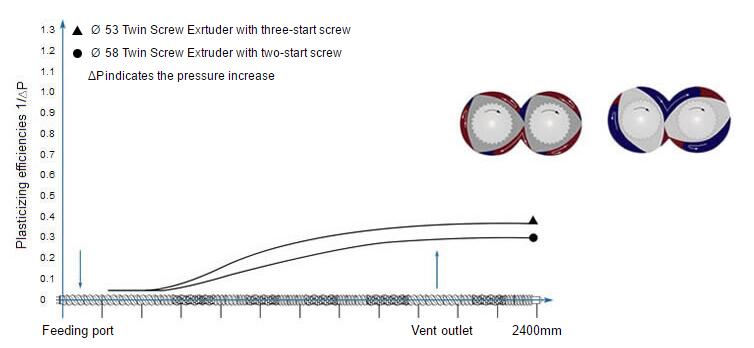

Dispersion effect of an 48:3 pigment powder(30%)in PP(70%)

4. Wear resistance: our scientific approach in selecting screw shaft and barrel materials, backed by advanced heat treatment

technology, ensures an exceptional wear resistance so that the machine's uniform screw engagement clearance will be preserved.

5. Interchangeability: by replacing the barrel and screw shaft, our three-start twin screw extruder can be converted into a

two-start twin screw unit.

6. Special structure

7. Water cooling of the screw shaft, starting from the internal core shaft, is available as an option. The customer can choose

the solution which meets his requirements.

8. Selectable multi-feed and multi-point venting options.

9. Standardization: a standardized screw shaft and core-barrel design is employed across our triple screw extruder,twin

screw extruder and blend reactor lines.

10. Materials undergo shear three times per screw revolution.

11. The triple groove conveyor provides smoother conveying action; output is guaranteed.

12. A thicker core shaft can deliver and support higher torque levels.

13. An increased screw surface area, making for an enlarged area of contact between the screw and processed material, provides a more uniform and more thorough shearing action.

14. Multiple but smaller shear and dispersion volumes during operation can reduce wear of the screw thread.

15. At the feeding port, materials are being delivered via two screw elements plus 6 additional threaded screw feeding grooves – equivalent to a 1/3 increase in material mixing effectiveness. Moreover, our shallow groove structure provides an earlier onset of shear and hence, plasticizing action, plus smoother degassing.

16. Inside the barrel, as the material moves from a transfer section to the kneading zone and on to the next transfer section, a process of mixing three parts of material into one, followed by renewed separation into three parts, is continuously carried out for superior mixing performance.

17. In the venting zone, the amount of material in contact with the screw surface area increases – as materials become thinner, the degassing effect is greatly improved.

18. Dispersion performance: compared to a two-start screw, a more continuous, more powerful and more homogeneous shearing force is delivered, improving the mixing and dispersion of polymers. In masterbatch processing, pigments are dispersed more thoroughly and the much increased quantity of nanoscale particles is more uniformly dispersed for a better coloring effect. In polymer blending, a greatly enhanced intermixing performance is achieved (see figure).

19. Applications: plastification of thermoplastic polymers, micro blending of rubber and plastics, nanoscale powder dispersion in polymers, production of coating powders, food processing, chemical reactions, etc.

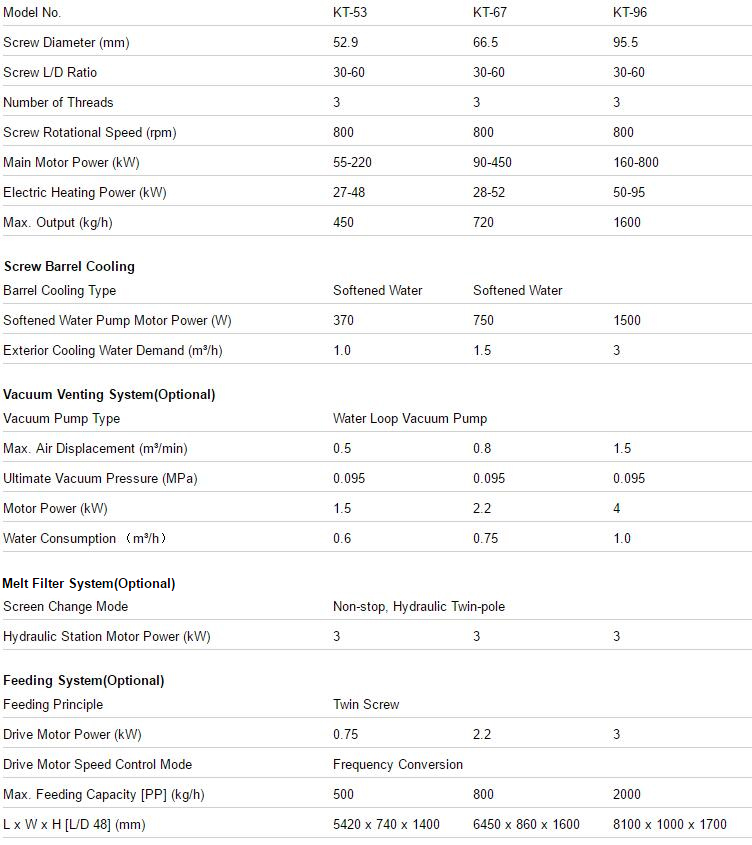

Twin Screw Extruder Technical Data:

| Model No. | P25 |

| Description | Filter Pressure Value Tester |

| Screw Diameter | 25mm |

| Suitable Materials | Thermoplastic polymers |

| Model No. | 3D-1 | 3D-1 BICO |

| Description | 3D Printer (Screw Type) | 3D Printer (Screw Type) |

| Screw Diameter | 6mm | 6mm |

| Suitable Materials | Thermoplastic polymers | Thermoplastic polymers |