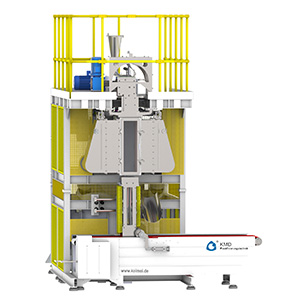

Single-hole Spunbond benchtop lap equipment

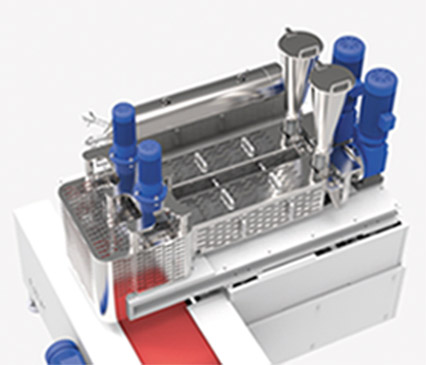

Single-hole Meltblown benchtop lap equipment

Melt-blown Nonwovens Lab Equipment-Bi-component

units

Melt-blown Nonwovens Lab Equipment-Mono-component

units

Spun-bond Nonwovens Lab Equipment - Bi-component

units

Spun-bond Nonwovens Lab Equipment - Mono-component

units

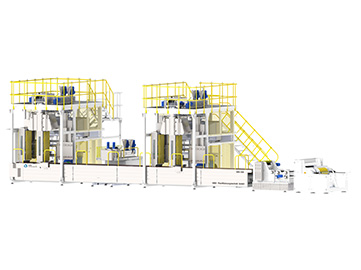

SMS Nonwovens Lab Equipment - Bi-component units

SMS Nonwovens Lab Equipment - Mono-component units

General characteristics:

Suitable for a wide range of thermoplastic polymers, e.g., PP, PA, PET, PLA, etc.

Easy to clean, channels where the melted materials flow smoothly; no need to be

disassembled for cleaning. The materials are easier to change.

The temperature of the quenching is adjustable between 15~25℃.

The height of the quenching is adjustable to meet the application needs for the

crystallization and cooling of different polymeric materials.

Cantilever structure, easy experimental operation, easy experimental observation.

The type of spinneret aperture is variable.

Thermal bonding device with a unique electrical heating system for more flexible and

convenient temperature control.

Thermal bonding system can be equipped with a variety of pressure rolls with different

patterns, also suitable for use in the technology of Spun-lace nonwovens.

The combination of the equipment can be configured according to application needs, such

as SS, SMS, SSMMS, etc

Change from mono-component to bi-component : only necessary to add the extruder and

spinning modules.

Change from bi-component to mono-component : a. interchangeable spinning module ; b. use

the same material

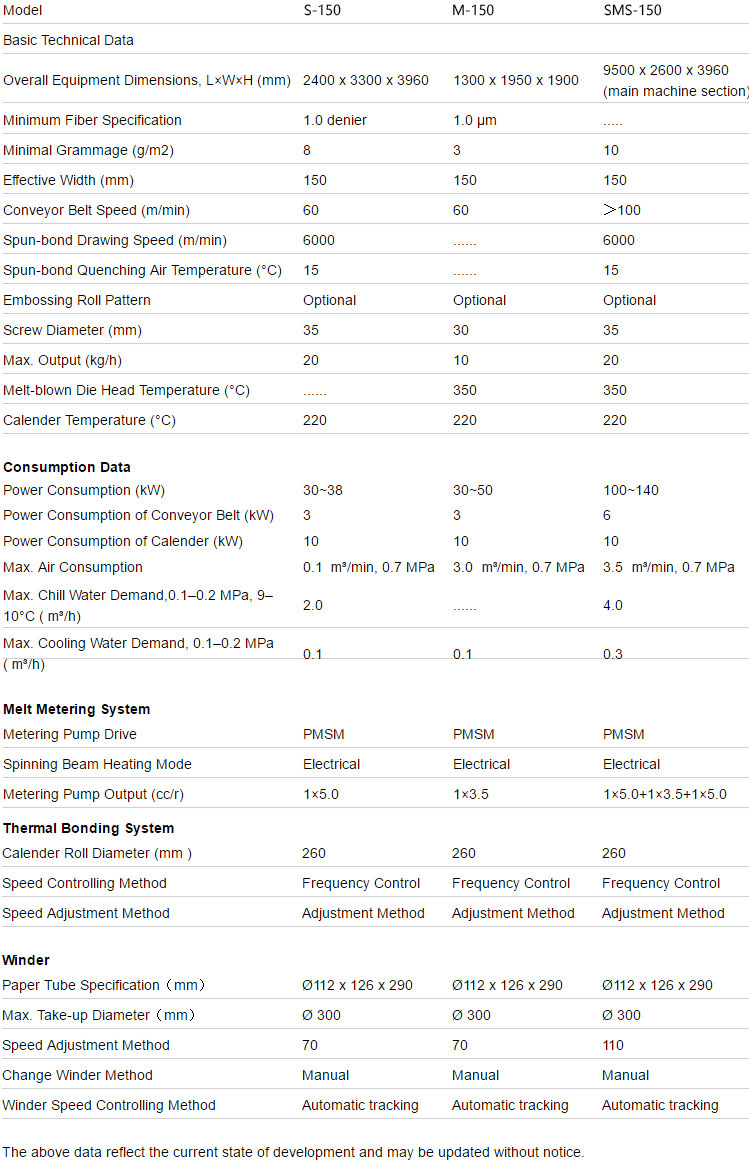

Technical Data of Nonwoven Lab Equipment for Mono-component

(Please contact us for bi-component if required)